-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Software Download

- Manual

- Video

- Tutorial

Sort in TubesT means to optimize the cutting sequence of graphics.

Functions

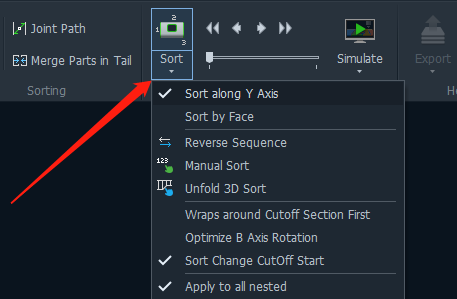

TubesT has various sequencing methods. Click Sort and you will see options in the dropdown.

1. Sort along Y Axis

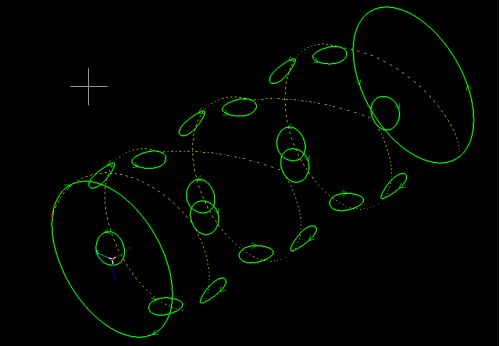

Y-axis is the extension direction of the pipe. The parts are sorted from small to large according to Y coordinates, which means to sort parts from the pipe head to the pipe tail. Starting from the Y coordinate near the starting section, it moves along the direction of the pipe to the end of the pipe, and the sequence of graphics is the sequence of Sort.

If two graphics have the same starting point on the Y-axis, sort them in clockwise order.

The final sorting result is similar to a spring, arranged round and round from beginning to end. A typical sorting result is shown in the figure (the yellow line is travel path).

2. Sort by Face

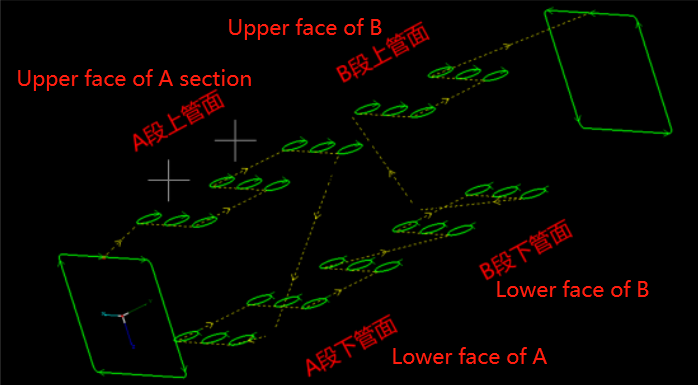

Sort by Face is for rectangular pipe, square pipe, special round pipe (assuming that the area within a small rotation angle of round pipe is regarded as a surface during machining). This sorting strategy will prioritize the graphics on the same surface together, sort each surface according to the strategy of Y coordinate from small to large and clockwise, and then turn to another surface after machining, so as to reduce rotations.

Sort by Face requires a setting named Segment length: The pipe is divided into sections by length, and each section will be sorted by face, instead of processing one single side at one time.

To reduce travel path, Sort by Face also optimizes the path when changing surfaces, so that the travel path is like “S” shape.

For example, in the following figure, the square pipe is divided into A section and B section via Segment Length. After processing the upper pipe surface of the A section, the pipe will be rotated to process the lower pipe surface of the A section; After machining the lower pipe surface of section A, the lower pipe surface of section B is directly machined instead of rotating to process the upper pipe surface of section B. From the path point of view, the rotation between segments is reduced and the path is optimized, with “S” shape.

This strategy has excellent sorting effect on parts with large number of graphics, similar size and neat position.

3. Manual Sort

Manual sorting is capable to set the cutting order completely as you like and change the starting position of the track at the same time.

4. Unfold 3D Sort

Unfold 3D Sort is an extension of manual sorting. It will expand three-dimensional graphics into two-dimensional one and sort the cutting path in two-dimensional space, which can solve the problem of difficult selection in three-dimensional space.

5. Wrap Cut-off Section First

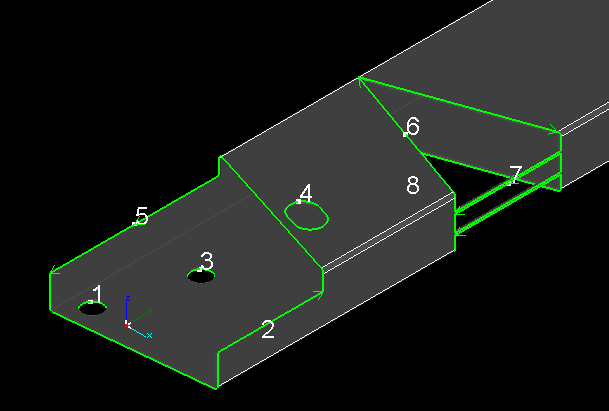

As shown in the figure, holes 1234 will be cut in front of path 5. This can avoid that cut-off section is cut ahead of holes and the pipe is stuck by the waste materials tilted up on the surface when retracting.

6. B-axis Rotation Optimization

If the servo motor of B axis uses absolute value encoder, and B axis rotates in the same direction all the time during the cutting, the feedback value of encoder will overflow to a certain extent, resulting in software alarm and cutting suspension. It is recommended to check this option if the B axis uses an absolute value encoder.

The result is that ① the cutting path direction alternates clockwise and counterclockwise in turn; ② The travel path direction of the pipe face alternates clockwise and counterclockwise in turn, and the B axis is controlled to be machined in a small circle range all the time.

7. Sort Change CutOff Start

If this function is enabled, it allows the software to adjust the starting point of the cut-off line, and in some cases, it can get a shorter travel path.

8. Apply to All Nested

If this function is turned on, each sort command will be applied to all nesting results.

Sort in TubesT means to optimize the cutting sequence of graphics.

Functions

TubesT has various sequencing methods. Click Sort and you will see options in the dropdown.

1. Sort along Y Axis

Y-axis is the extension direction of the pipe. The parts are sorted from small to large according to Y coordinates, which means to sort parts from the pipe head to the pipe tail. Starting from the Y coordinate near the starting section, it moves along the direction of the pipe to the end of the pipe, and the sequence of graphics is the sequence of Sort.

If two graphics have the same starting point on the Y-axis, sort them in clockwise order.

The final sorting result is similar to a spring, arranged round and round from beginning to end. A typical sorting result is shown in the figure (the yellow line is travel path).

2. Sort by Face

Sort by Face is for rectangular pipe, square pipe, special round pipe (assuming that the area within a small rotation angle of round pipe is regarded as a surface during machining). This sorting strategy will prioritize the graphics on the same surface together, sort each surface according to the strategy of Y coordinate from small to large and clockwise, and then turn to another surface after machining, so as to reduce rotations.

Sort by Face requires a setting named Segment length: The pipe is divided into sections by length, and each section will be sorted by face, instead of processing one single side at one time.

To reduce travel path, Sort by Face also optimizes the path when changing surfaces, so that the travel path is like “S” shape.

For example, in the following figure, the square pipe is divided into A section and B section via Segment Length. After processing the upper pipe surface of the A section, the pipe will be rotated to process the lower pipe surface of the A section; After machining the lower pipe surface of section A, the lower pipe surface of section B is directly machined instead of rotating to process the upper pipe surface of section B. From the path point of view, the rotation between segments is reduced and the path is optimized, with “S” shape.

This strategy has excellent sorting effect on parts with large number of graphics, similar size and neat position.

3. Manual Sort

Manual sorting is capable to set the cutting order completely as you like and change the starting position of the track at the same time.

4. Unfold 3D Sort

Unfold 3D Sort is an extension of manual sorting. It will expand three-dimensional graphics into two-dimensional one and sort the cutting path in two-dimensional space, which can solve the problem of difficult selection in three-dimensional space.

5. Wrap Cut-off Section First

As shown in the figure, holes 1234 will be cut in front of path 5. This can avoid that cut-off section is cut ahead of holes and the pipe is stuck by the waste materials tilted up on the surface when retracting.

6. B-axis Rotation Optimization

If the servo motor of B axis uses absolute value encoder, and B axis rotates in the same direction all the time during the cutting, the feedback value of encoder will overflow to a certain extent, resulting in software alarm and cutting suspension. It is recommended to check this option if the B axis uses an absolute value encoder.

The result is that ① the cutting path direction alternates clockwise and counterclockwise in turn; ② The travel path direction of the pipe face alternates clockwise and counterclockwise in turn, and the B axis is controlled to be machined in a small circle range all the time.

7. Sort Change CutOff Start

If this function is enabled, it allows the software to adjust the starting point of the cut-off line, and in some cases, it can get a shorter travel path.

8. Apply to All Nested

If this function is turned on, each sort command will be applied to all nesting results.

-

Download

-

Contact us

-

Online consultation