-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Software Download

- Manual

- Video

- Tutorial

(Basics) Machining Precheck

You have to do some precheck to confirm machine in good working status before click ‘Start’ button. CNC machining is extensible yet involves complex process. What position

on workpiece will start production? If the cutting will exceed the workpiece area? Be aware of these issues and get clear answers ahead of cutting task will ensure a smooth cutting

work. CypCut provides below options to precheck machining.

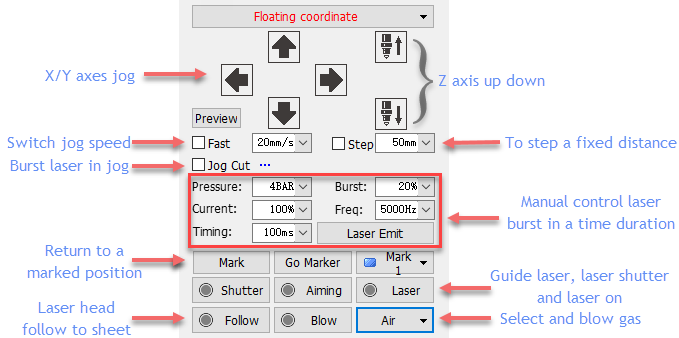

Check Machine Status

After start up machine, manually turn on/off laser, gas and guide beam, or jog/step motion axes to confirm machine in good working status. You can do this step by software button or

WKB hand-held box.

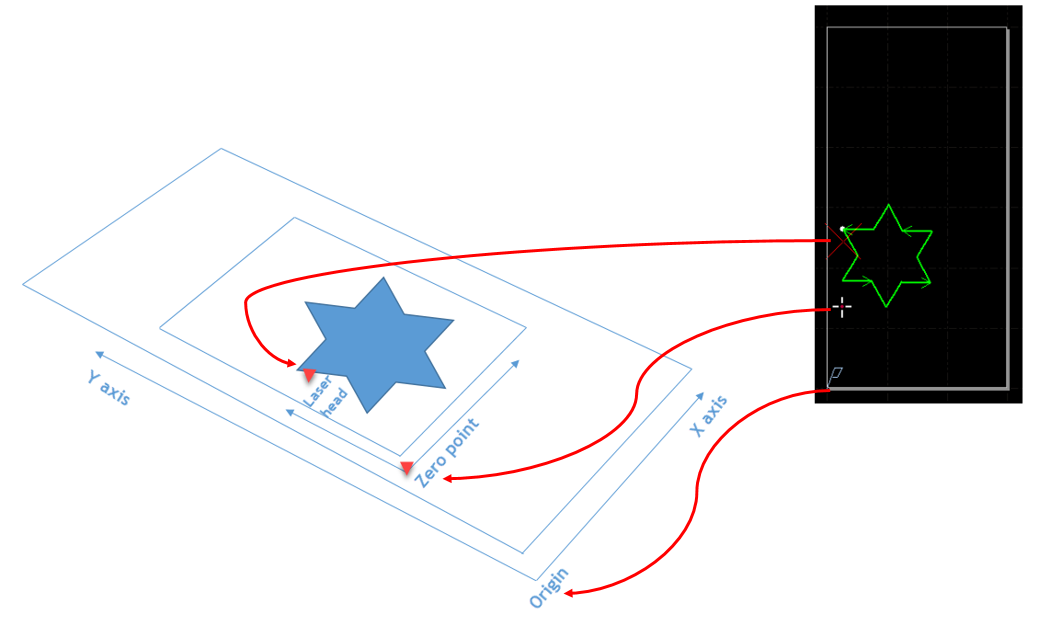

Preview on Drawing Board

The position change of graphic on drawing board will result in machine bed in production. Click  on control panel will refresh and display the relative position between laser head,

on control panel will refresh and display the relative position between laser head,

workpiece and machine travel range.

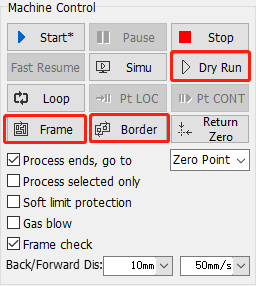

Cutting Area on Machine Bed

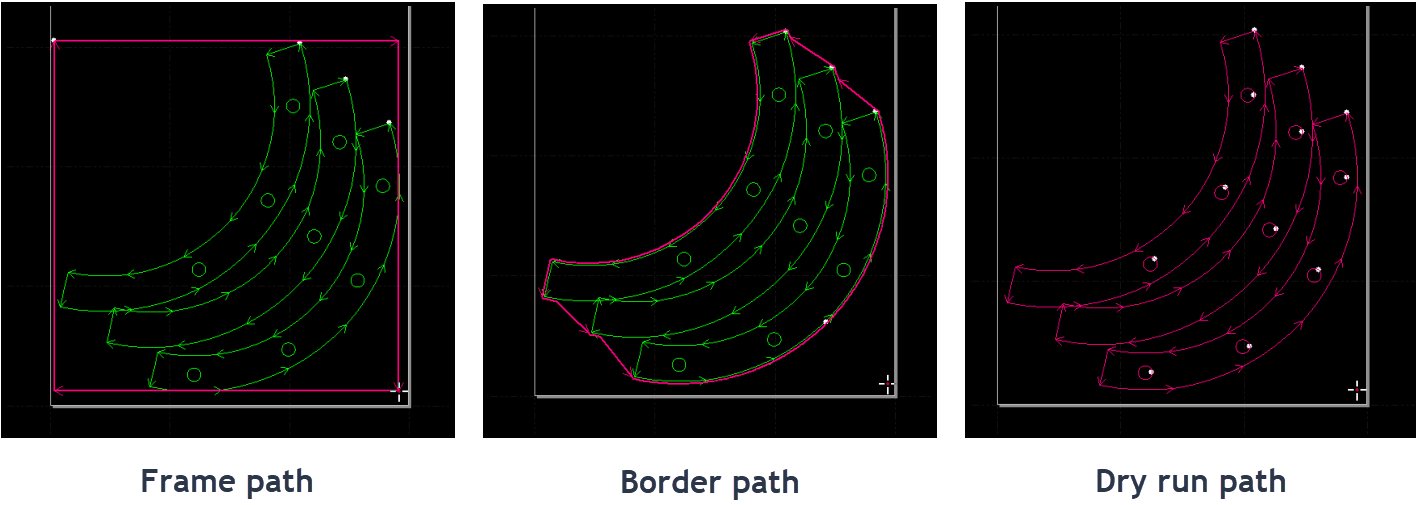

Frame is to check square border of part drawing to be cut. Machine will frame (dry run) the cutting zone on machine bed.

Border is to check along the outmost contour of the cutting area. The border contour is editable.

Dry Run is to travel along the toolpath not cutting it with gas, laser and PLC process all disabled.

Related Articles

(Basics) Machining Precheck

You have to do some precheck to confirm machine in good working status before click ‘Start’ button. CNC machining is extensible yet involves complex process. What position

on workpiece will start production? If the cutting will exceed the workpiece area? Be aware of these issues and get clear answers ahead of cutting task will ensure a smooth cutting

work. CypCut provides below options to precheck machining.

Check Machine Status

After start up machine, manually turn on/off laser, gas and guide beam, or jog/step motion axes to confirm machine in good working status. You can do this step by software button or

WKB hand-held box.

Preview on Drawing Board

The position change of graphic on drawing board will result in machine bed in production. Click  on control panel will refresh and display the relative position between laser head,

on control panel will refresh and display the relative position between laser head,

workpiece and machine travel range.

Cutting Area on Machine Bed

Frame is to check square border of part drawing to be cut. Machine will frame (dry run) the cutting zone on machine bed.

Border is to check along the outmost contour of the cutting area. The border contour is editable.

Dry Run is to travel along the toolpath not cutting it with gas, laser and PLC process all disabled.

Related Articles

-

Download

-

Contact us

-

Online consultation