-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

BOCHU High-Speed Servo Drive

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Technical Data

- Hardware

- Software

- Manual

- Certificate

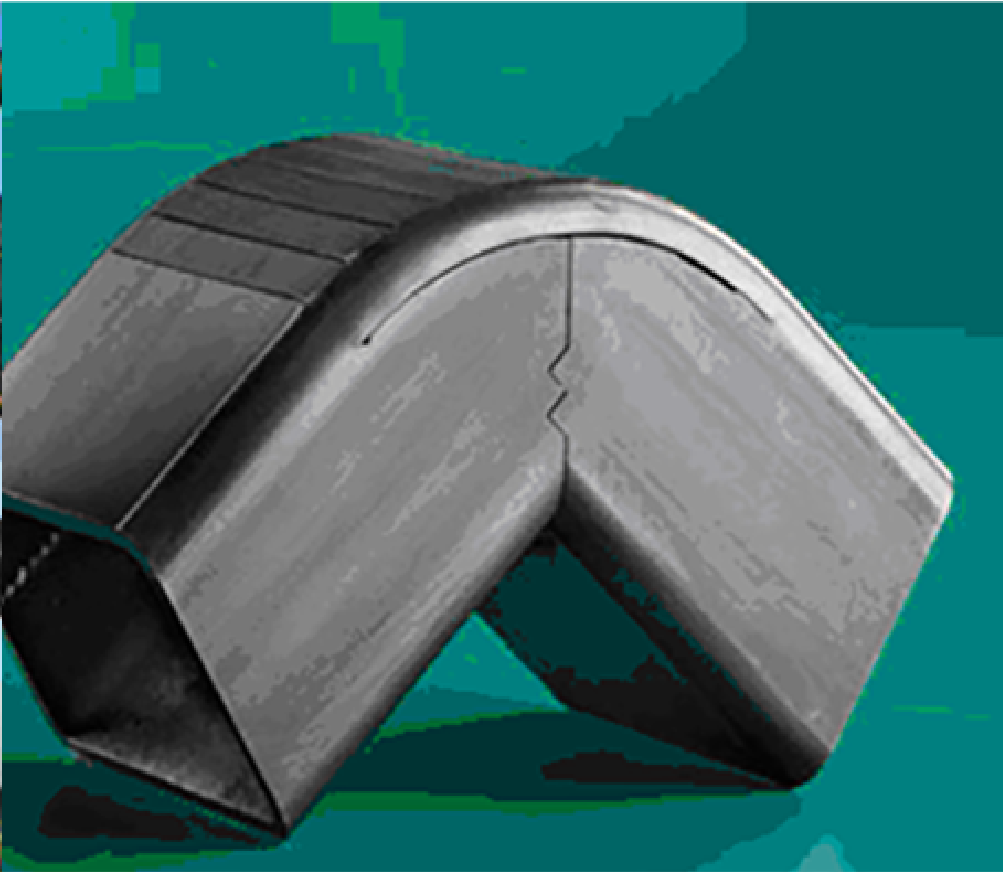

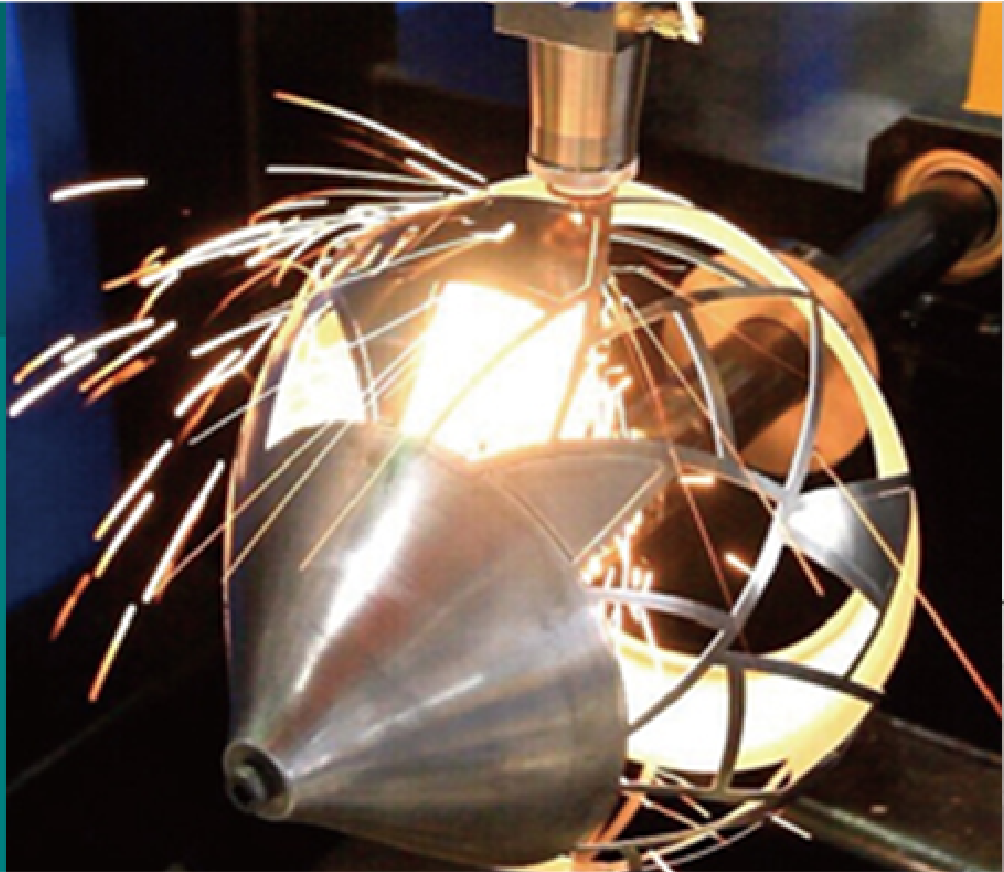

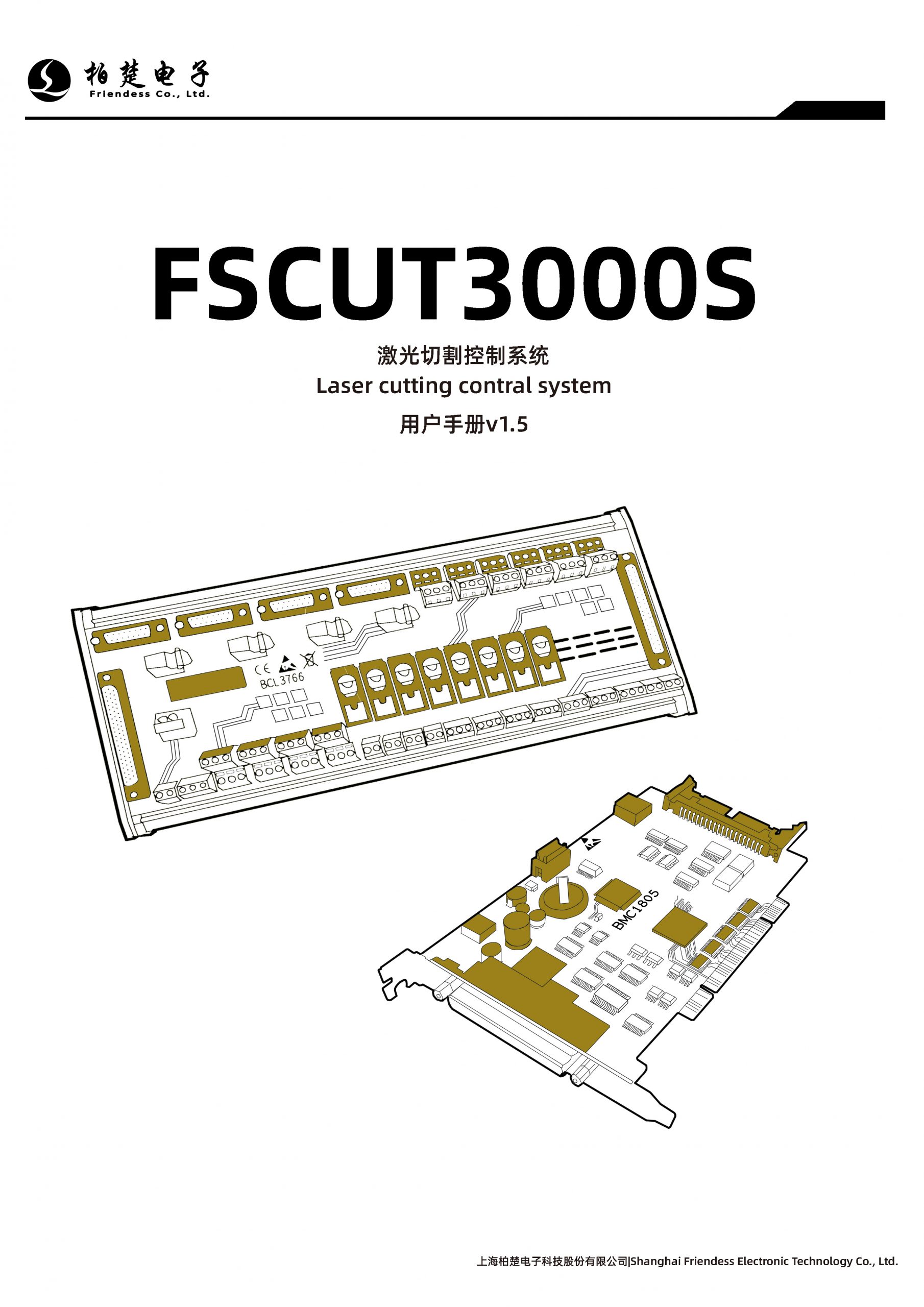

FSCUT3000S system is designed for tube cutting control, support standard tube(retangle, circle, oval, ellipse and obround etc.) , free form , and steel channels(T/U/H/L shape) production of high precision and efficiency.

Technical Data

Model

FSCUT3000S

Software

TubePro tube cutting software/ CypCut sheet cutting software

Control card

BMC1805

Interface type

32-bit PCI bus, 132MB/S

I/O terminal board

BCL3766

Power supply

24V DC/2A

Motor control

X/Y1/Y2/W axis pulse output, heighest frequency 3MHz

X/Y1/Y2 axis access encoder feedback, highest sampling frequency 10MHz

W axis port can be assigned to rotary axis or autofocus unit

Work environment

Temperature: 0-55 ℃

5%-95% (no condensation)

Dedicated input

8 limit inputs:Positive and negative limit for X/Y1/Y2/W axis

4 origin inputs:X / Y1 / Y2 / W axis origin

Dedicated output

2 DA: 0~10V,50mA

1 PWM with 5V/24V for option, precision of 5KHz (0.1%)

Common input

15 inputs: 12 are low-level active, 3 inputs can jump-wire switch to high-level active.

Common output

8 relay output, load capacity 250V AC/5A, 30V DC/5A

12 thyristor output, DC 24V/500mA

Benefits

Cutting technique

Support offset tube center error in production to improve through holes cutting precision.

Support steel channels cutting.

Suppport seperate technique for corner cutting.

Support auto loading/unloading process, cycle production and automatic tube feeding.

Support all functions of FSCUT2000 system.

Control performance

Open-loop control system, Friendess 5th generation motion control algorithms.

Trajectory accuracy 0.02mm, positioning accuracy 0.001mm, repeatability 0.003mm.

Access encoder feedback in real time, to compare command and machine toolpath.

Application

Applied in tube cutting or tube-sheet combo machine. Widely used in furniture, display shelf, architecture, and sport equipment industries.

Components

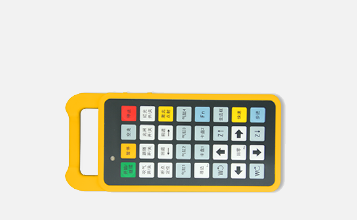

WKB

Wireless hand-held remote

Number:1

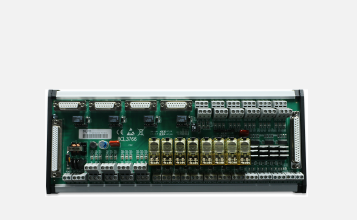

BCL3766

I/O terminal board

Number:1

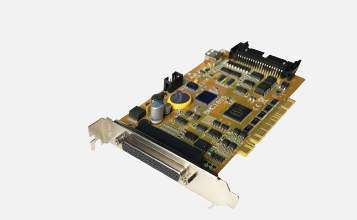

BMC1805

PCI Control card

Number:1

Accessories

C62-2/5/10

62-pin cable

Number:1

C37-2/5/10

37-pin cable

Number:1

C15-1.5/2.5/4

Servo cable

Number:4

TubesT

TubesT

TubesT is a 3D tube nesting software designed for CypTube/TubePro laser cutting system. From parts drawing and modification, full type compensation, strategic nesting to report generation, using TubesT will meet and exceed your production needs.

TubePro

TubePro

TubePro designed for professional tube cutting, supports production of tube and profile of various shape. It works with TubesT nesting software seamlessly to realize technique setting, advanced toolpath generation and nesting for standard and special production need.

TubesT-Lite

TubesT-Lite

TubesT-Lite is a free software to generate toolpath for FSCUT tube cutting system. It's designed for CypTube/TubePro, can import part from external igs file, draw the part of standard shape and array-nest the part on the tube.

×

-

Download

-

Contact us

-

Online consultation