-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Technical Data

- Hardware

- Software

- Manual

FSCUT4000E is a cost-effective laser control system applies to 1.5-8KW power cutting. Based on EtherCAT, integrating motion control, laser control, and gas control, it widely applies to metal sheet, cookware and lamps cutting.

Fast Cutting

speed up sheet cutting

Smooth MicroJoint

batch unload, piece of cake

Circle Centering

locate the center on circular sheet metal and processing

One-Path FlyCut

create fly cutting paths for any shapes to improve cutting efficiency

Scan-to-Import

read drawings with a simple scan

Envelope Check

contouring for non-rectangular sheet metal

Components

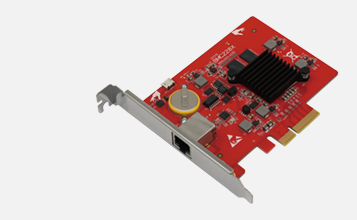

BMC228B

master card bmc228a

Number:1

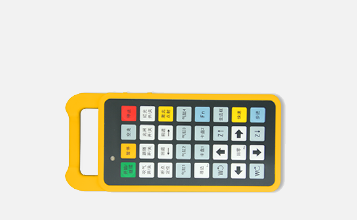

WKB

Wireless hand-held remote

Number:1

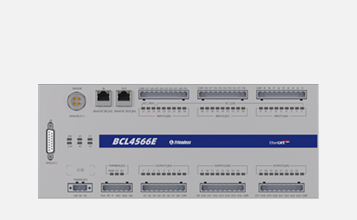

BCL4566E

BCL4566E terminal board

Number:1

BCL-AMP

Preamplifier

Number:1

Accessories

SPC-140/SPC-180/140B/180B

RF cable

Number:2

HC-15

4-pin cable

Number:1

LAN-3X/LAN-0.3X/1X/7X/17X

Network cable

Number:5

CypNest

CypNest

CypNest is a nesting software designed for CypCut/HypCut sheet laser cutting system. It integrates advanced functions of drawing modification, quick nesting, toolpath generation, analysis report and more to meet your production needs.

CypCutE

CypCutE

Friendess CypCutE 2D cutting software is for medium power EtherCAT cutting system. CypCutE is easy to use, rich in functions, stable and reliable. It has advanced functions such as "Smooth MicroJoint", "Fast Cutting" and "Circle Center" to meet various processing needs.

×

功能视频

切割头维护视频

-

Download

-

Contact us

-

Online consultation