-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Software Download

- Manual

- Video

- Tutorial

- Part Drawing

It is allowed to create the part by the option Draw a Part in TubesT.

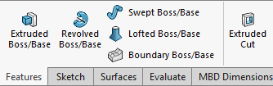

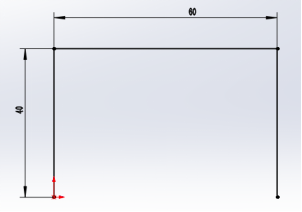

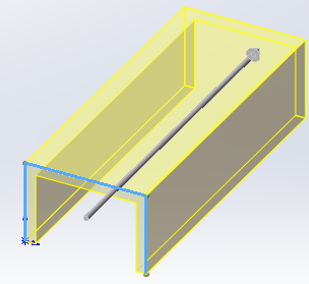

If you’re going to third-part CAD software like SW to create a part, the standard way is to draw a section first, then Extrude Boss/Base and Cut.

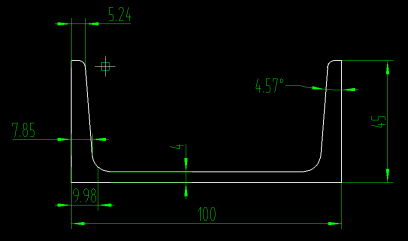

If the Angle Steel to be created has uneven thickness as the above, you can just draw it with thickness 4 and no inner fillets, or it will lead to Wrong Identification or Weld Kerf Compensation problem.

Notes:

(1) Thickness should be same, or TubesT may recognize the part as Closed Free-formed part but not Angle Steel or Channel Steel.

(2) No fillets. Generally the cutting of Channel or Angle Steel is introduced outside the plate to cut in sections, if it has chamfers, the rotary axis will move during the cutting resulting in sudden changes in the thickness of the cut quality is difficult to guarantee (thickness less than 2 mm, no need to cut in sections, using a direct cut of channels or angles please draw the chamfer according to the actual).

(3) If you’re using TubesT to draw Angle Steel or Channel beam, the above can be avoided automatically.

- Import to TubesT

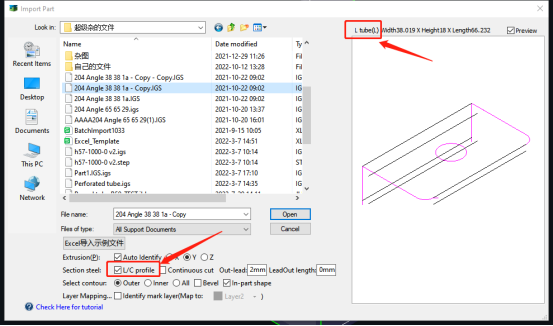

If you’re going to import the IGS/SAT/STEP files finished in third-party CAD software to TubesT by Import Files, please check the option L/C Profile as below and ensure there is L Tube title identified.

- Special Cutting Path

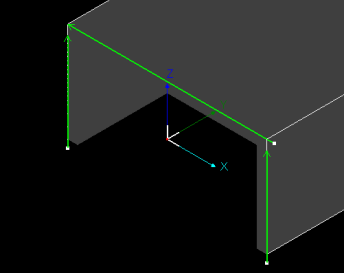

Different with TubesT-Lite, TubesT will generate special cutting path for L/C profiles, as shown below, the C-shaped profile has three separate cutting paths to get a cut-off section.

- Clamping Direction

Angle Steel differs in Left and Right direction, so it is recommended to confirm whether the preview in TubePro is corresponding to actual clamping posture.

As shown below, this angle steel is R type, which means its another side is on the right.

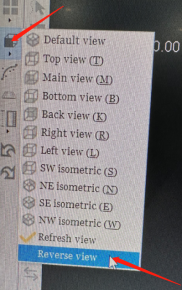

If the preview in TubePro is already in the opposite direction of actual position and you do not want to re-clamp it correctly, it is possible to apply Reverse View in TubePro to reverse pipe’s direction.

- Center Before Actual Processing

Generally it is necessary to do Single Surface Leveling before Center.

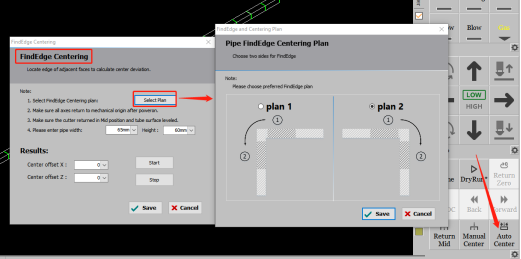

For the drawings of angle/channel steel imported, TubePro will consign proper Center methods for them automatically as shown below.

There are two Center methods named L Beam Centering and FindEdge Centering, which have little difference with each other. To be simple, if the angle of L/C steel is not 90°, then L Beam Centering is recommended, or the other will be better.

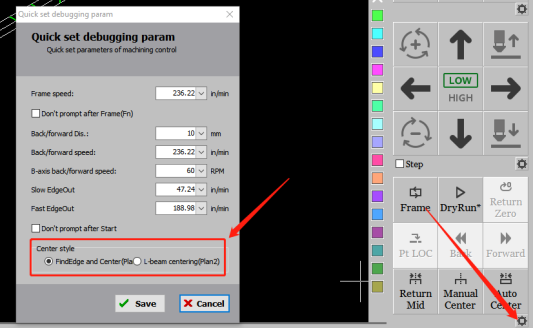

And these two Center methods can be alternated in Quick Set Debugging Params window as shown below,

Each Center method has Plan1 and Plan2 as there is no need to execute FindEdge action for third surface on C-shape profile, which leads to that L Steel and C Steel has the same Center methods. Although, TubePro will consign Plan1 or Plan2 for L Steel imported automatically, which also is suitable for C Steel, so it is allowed to alternate these two manually.

- Special Case: Two Angle Steels of Same Size Are Recognized As Two Parts

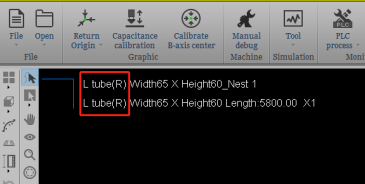

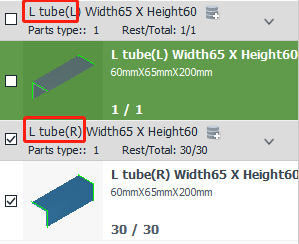

The angle steel with two same sides may be recognized as L and R types respectively, which can not be nested together as shown below.

You can check how to deal with it in Unify Identical Parts.

- Part Drawing

It is allowed to create the part by the option Draw a Part in TubesT.

If you’re going to third-part CAD software like SW to create a part, the standard way is to draw a section first, then Extrude Boss/Base and Cut.

If the Angle Steel to be created has uneven thickness as the above, you can just draw it with thickness 4 and no inner fillets, or it will lead to Wrong Identification or Weld Kerf Compensation problem.

Notes:

(1) Thickness should be same, or TubesT may recognize the part as Closed Free-formed part but not Angle Steel or Channel Steel.

(2) No fillets. Generally the cutting of Channel or Angle Steel is introduced outside the plate to cut in sections, if it has chamfers, the rotary axis will move during the cutting resulting in sudden changes in the thickness of the cut quality is difficult to guarantee (thickness less than 2 mm, no need to cut in sections, using a direct cut of channels or angles please draw the chamfer according to the actual).

(3) If you’re using TubesT to draw Angle Steel or Channel beam, the above can be avoided automatically.

- Import to TubesT

If you’re going to import the IGS/SAT/STEP files finished in third-party CAD software to TubesT by Import Files, please check the option L/C Profile as below and ensure there is L Tube title identified.

- Special Cutting Path

Different with TubesT-Lite, TubesT will generate special cutting path for L/C profiles, as shown below, the C-shaped profile has three separate cutting paths to get a cut-off section.

- Clamping Direction

Angle Steel differs in Left and Right direction, so it is recommended to confirm whether the preview in TubePro is corresponding to actual clamping posture.

As shown below, this angle steel is R type, which means its another side is on the right.

If the preview in TubePro is already in the opposite direction of actual position and you do not want to re-clamp it correctly, it is possible to apply Reverse View in TubePro to reverse pipe’s direction.

- Center Before Actual Processing

Generally it is necessary to do Single Surface Leveling before Center.

For the drawings of angle/channel steel imported, TubePro will consign proper Center methods for them automatically as shown below.

There are two Center methods named L Beam Centering and FindEdge Centering, which have little difference with each other. To be simple, if the angle of L/C steel is not 90°, then L Beam Centering is recommended, or the other will be better.

And these two Center methods can be alternated in Quick Set Debugging Params window as shown below,

Each Center method has Plan1 and Plan2 as there is no need to execute FindEdge action for third surface on C-shape profile, which leads to that L Steel and C Steel has the same Center methods. Although, TubePro will consign Plan1 or Plan2 for L Steel imported automatically, which also is suitable for C Steel, so it is allowed to alternate these two manually.

- Special Case: Two Angle Steels of Same Size Are Recognized As Two Parts

The angle steel with two same sides may be recognized as L and R types respectively, which can not be nested together as shown below.

You can check how to deal with it in Unify Identical Parts.

-

Download

-

Contact us

-

Online consultation