-

Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

-

Portfolio

-

-

2D Cutting Head

Tube Cutting Head

Plane Bevel Cutting Head

Structural Steel Cutting Head

-

BOCHU High-Speed Servo Drive

-

Popular products

-

- Online Store

- Service & Support

- About BOCHU

- Investors Relations

- Software Download

- Manual

- Tutorial

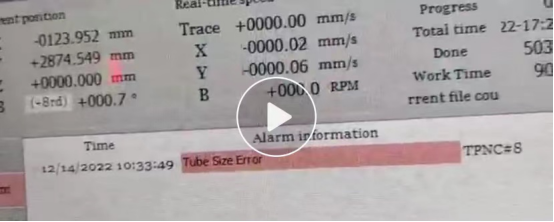

When you execute Center, it may give such an error if actual tube size it not consistent with the drawing size.

Cause Analysis.

When the software is centering (4-point Center for example), the coordinates obtained from centering are Z1, Z2, Z3 and Z4.

Theoretically, if the chuck is clamped properly, the Z1 coordinate (theoretical value) = the Z coordinate of the B-axis center (negative) + H/2. H is the length of the pipe section provided in the drawing.

If the actual Z1 coordinate obtained in Center is more than 10mm different from the Z1 coordinate (theoretical value), the software will think that the tube is clamped too far to the right situation, or the drawing is drawn with wrong dimensions, and an alarm will occur.

Possible Factors

1, check the tube clamping to see if the clamping is crooked.

2, check whether the dimensions of the drawing are consistent with the actual (note that the radius and diameter of the round tube may be wrong)

3, check the stability and accuracy of z-axis following.

(1) whether the Z-axis pitch is set right; (after the z-axis back to the origin, point the z-axis touches the plate surface, observe the z-coordinate of the main interface of the height controller, if the z-coordinate = the actual z-axis drop distance, which means the pitch is normal)

(2) whether the Z-axis screw is slipping.

(3) whether the result of Capacitance Calibration is all excellent.

4, Re-calibrate B axis with a standard rectangular tube which has no chamfers, and then execute Center with to-be-machined tubes.

5, If this alarm occurred when calibrating B axis, you need to check x-axis pitch and whether z-axis gain level is too low.

When you execute Center, it may give such an error if actual tube size it not consistent with the drawing size.

Cause Analysis.

When the software is centering (4-point Center for example), the coordinates obtained from centering are Z1, Z2, Z3 and Z4.

Theoretically, if the chuck is clamped properly, the Z1 coordinate (theoretical value) = the Z coordinate of the B-axis center (negative) + H/2. H is the length of the pipe section provided in the drawing.

If the actual Z1 coordinate obtained in Center is more than 10mm different from the Z1 coordinate (theoretical value), the software will think that the tube is clamped too far to the right situation, or the drawing is drawn with wrong dimensions, and an alarm will occur.

Possible Factors

1, check the tube clamping to see if the clamping is crooked.

2, check whether the dimensions of the drawing are consistent with the actual (note that the radius and diameter of the round tube may be wrong)

3, check the stability and accuracy of z-axis following.

(1) whether the Z-axis pitch is set right; (after the z-axis back to the origin, point the z-axis touches the plate surface, observe the z-coordinate of the main interface of the height controller, if the z-coordinate = the actual z-axis drop distance, which means the pitch is normal)

(2) whether the Z-axis screw is slipping.

(3) whether the result of Capacitance Calibration is all excellent.

4, Re-calibrate B axis with a standard rectangular tube which has no chamfers, and then execute Center with to-be-machined tubes.

5, If this alarm occurred when calibrating B axis, you need to check x-axis pitch and whether z-axis gain level is too low.

-

Download

-

Contact us

-

Online consultation